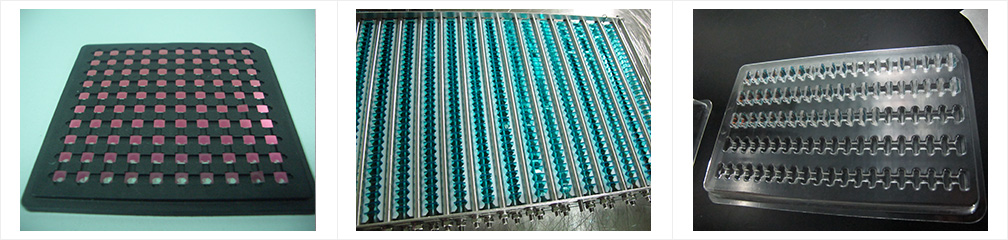

IR Filter can cut-off infrared rays reached to Sensor. By attaching IR Filter to skin on lens unit or holder, it will be able to eliminate an appeared error such as flickering Image while taking a picture. Alpha Optik can process the circle and square filter with each grade of Mega Pixel (20um) and VGA (30 um) with a custom-designing.

Alpha Optik IR cut-off filter can sharply cut infrared ray.

1.There is the specialist crystal technology: from cutting, polishing, flatness technology, cleaning, coating, combining technology.

2.Angle cutting tolerance improving from +/-0.3’ to +/-0.1’; thickness tolerance improving from +/-0.05 TO +/- 0.025mm, and cutting speed improving from 1.2mm/H to 9mm/H, all by ourself-made Multi-cutting machine.

3.The flatness technology can let the 4 angle and 8 sides be polishing at the same time. And the quality can be improved about 50%;

OLPF———————————————–3KK/M;

Crystal Thermal Diffusion Panel————-500K/M;

Blue thermal Diffusion Panel—————–100K/M;

IR filter———————————————-7KK/M;

Single OLPF

| Iterm | Standard | Special | ||

| Size of Substrate | Size | 1/2sensor | 9.2X10.4, 11X12(mm) | Customized |

| 1/3sensor | 7.3X8.2, 8.2X8.8, 9X10(mm) | Customized | ||

| 1/4sensor | 6.5X7.3, 7.3X7.8(mm) | |||

| 1/6sensor | 5.3X6.0, 5.8X6.3(mm) | Customized | ||

| Tolerance | ±0.1mm | – | ||

| Thickness

/quality |

Thickness

tolerance |

0.30±0.02mm | ||

| 0.40±0.02mm | ||||

| 0.50±0.03mm | ||||

| 0.55±0.03mm | ||||

| 0.70±0.05mm | Customized | |||

| Surface roughness | ±0.05mm,±0.03mm | – | ||

| Coating

|

Single coating | Reflect 1.5% max./550nm | – | |

| Multi coating | Reflect 1.0% max./450-650nm | – | ||

| Chip and dot | Under 30um | – | ||

| Efficiency Scopes | 1mm to the side | Customized | ||

| Reliability (60℃,90%) | Two side mult-coating | 300H,500H | – | |

| IR cut coating | 300H | Customized | ||

Thermal diffusion panel is the key parts of Projector optical engine , which can diffuse the projector hot and let it work well…

| Term | specification |

| Diameter ( Tolerance) | 40 mm max. ( 0.2 mm) |

| Thickness(Tolerance) | <0.3 mm min. ( 0.1mm) |

| Eccentricity (tolerance) | ±1° |

| Chip dot | <100 μm |

| single side AR coating | < 1 % (420 to 680 nm) |

| Size | thickness |

| 36×30 | 0.7 |

| 28×22 | 0.5 to 0.7 |

| 25.5×25.5 | 2 |

| 23.5×20 | 0.5 to 1.4 |

| 20×18 | 0.5 |

| φ26×16 | 1.4 |